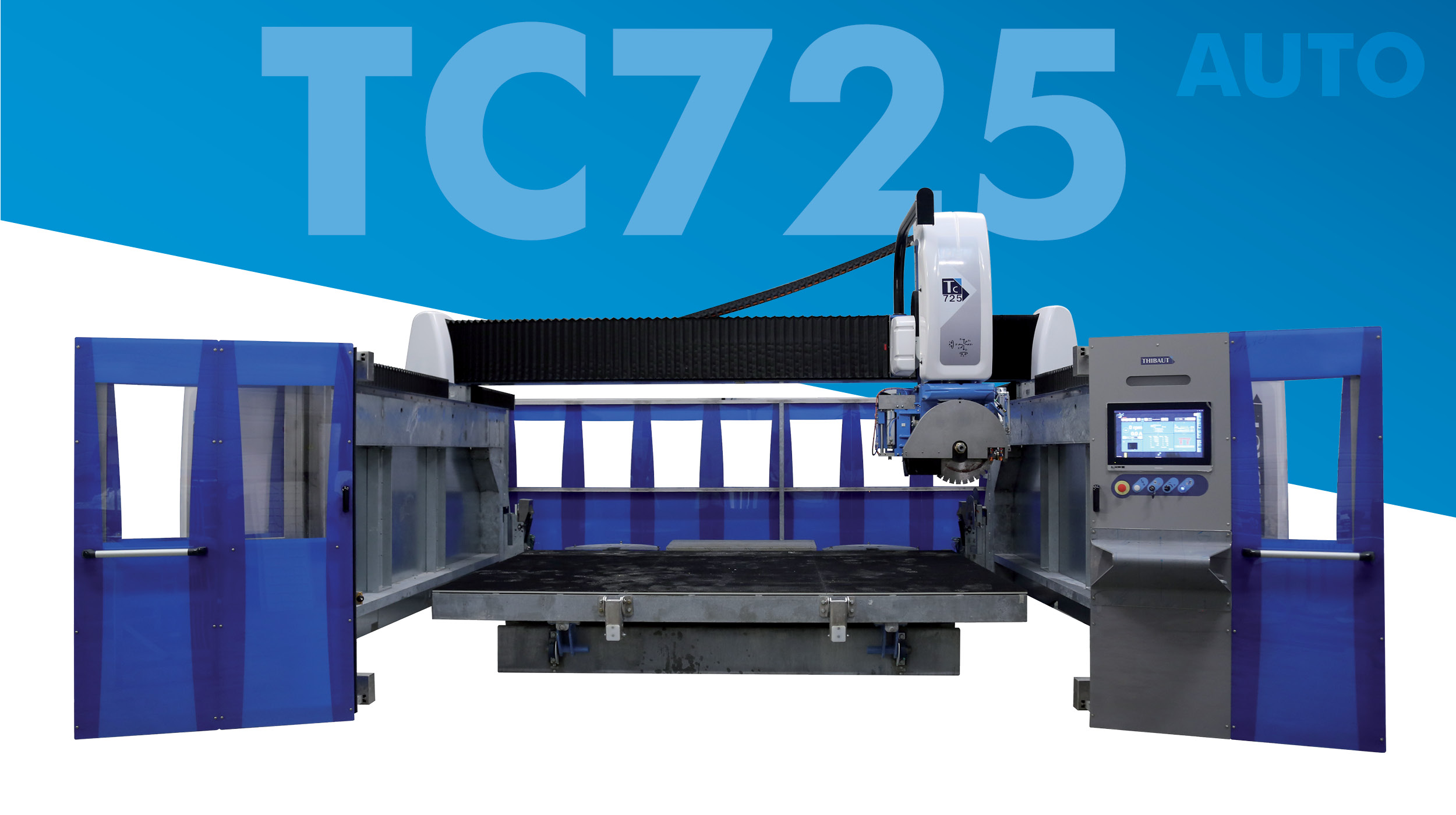

The TC725 AUTO is a true 5-axis numerically controlled sawing and shaping centre. It allows you to make cuts in all directions automatically, up to a thickness of 250 mm, or to shape parts of any shape. Thanks to its automatic tool change, this cutting machine will allow you to adapt more easily and quickly to all kinds of tools adapted to your production.

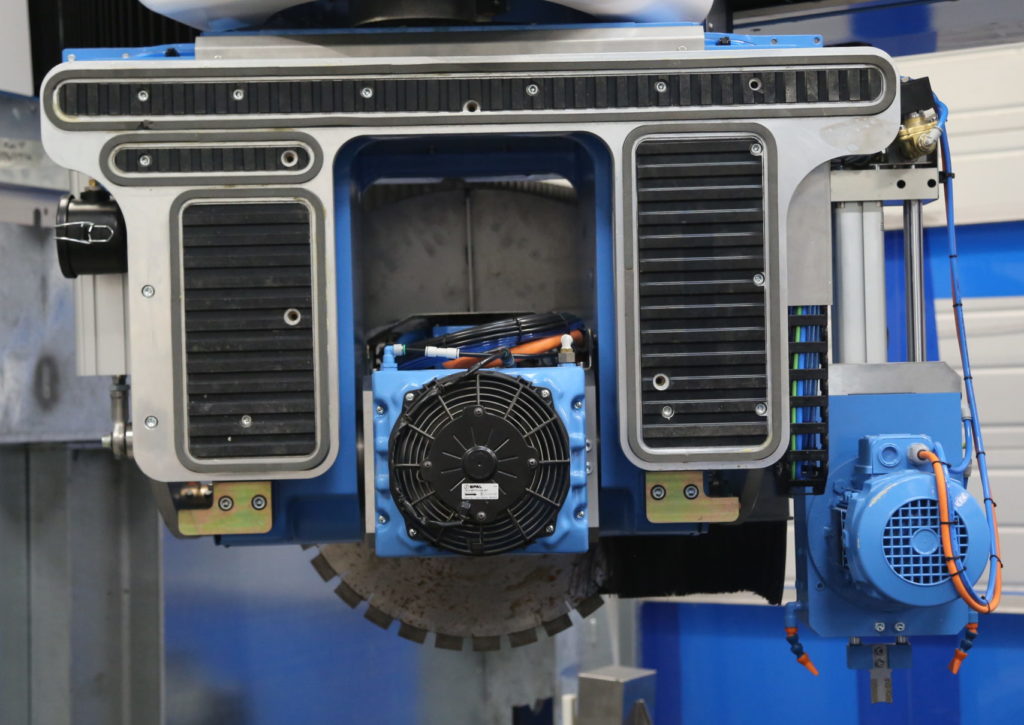

The powerful TC725 AUTO has a spindle power of up to 19.9 kW (S6). Its variable speed from 0 to 6000 rpm and its various options give it a very high autonomy and allow it to carry out all types of operations such as drilling, profiling, routing, sawing, mitre cutting, brushing, etc.

| Working capacity | mm |

|---|---|

| Stroke X | 3700 |

| Stroke Y | 3700 |

| Stroke Z | 700 |

| Sawing capacity | mm |

|---|---|

| Cutting thickness | 250 |

| Min. disc diameter | 350 |

| Max. disc diameter | 750 |

| Axes | Speed m/min |

|---|---|

| X | 40 |

| Y | 40 |

| Z | 15 |

A-axis tilt: 0°/90°

C-axis rotation: ±200°

Spindle motor power: 19.9kW (S6)

Tool rotation speed: 0/6000 tr/min

Total weight: 7300 kg

| Cross Laser | Line Laser |

| Mechanically welded walls | Quick-opening housing |

| Touch-screen remote control | Working table 3600x2000mm |

| Retractable front stops | Machine doors with 19″ console |

| Electrical cabinet | 1/2 gas adapter for tools |

| Linear tool magazine 8 slots | Blade housing magazine |

| Blade magazine |

| Watering for milling tools | Large size flange |

| Camera | Abrasive stone for tool sharpening |

| ACS (Angle Cut Solution) | AVS (Automatic Vacuum Solution max. 750kg) |

| Tilting table | Slab thickness sensor |

Included:

| Pilot® | Interface developed by Thibaut

|

| Express Jobs | Powerful program including parametric shapes, very easy to use |

| T’Shape 3D shaping software |

| T’Cut 2D cutting software |

| Vein Matching Software Software for 3D visualization of pieces with their veins |

| eT’CAM 2D shaping software designed for decoration |

| T’CAD/T’CAM 3D design and shaping software |

M: A mechanically welded structure consisting of low walls on feet

AUTO: With automatic tool change

TOPS (Thibaut Optimized Processing Solution): Through-feed system to optimize the production of slabs

Our machines are connected to the internet and equipped with remote connection software with a firewall. This allows quick diagnosis and remote intervention by our Thibaut Customer Service technicians.

A Thibaut Customer Space will give you access to the available documentation of your Thibaut machines and you can make your requests to Thibaut Customer Service.

Quickly request a quote from your sales representative or via the contact form.