Interior decoration and ceramic slabs: what to do with the fiberglass mesh?

In the high-end interior decoration sector, ceramic has become an essential material. Resistant, aesthetic, thin, and easy to maintain, it is widely used for countertops, furniture, wall coverings, and custom finishes.

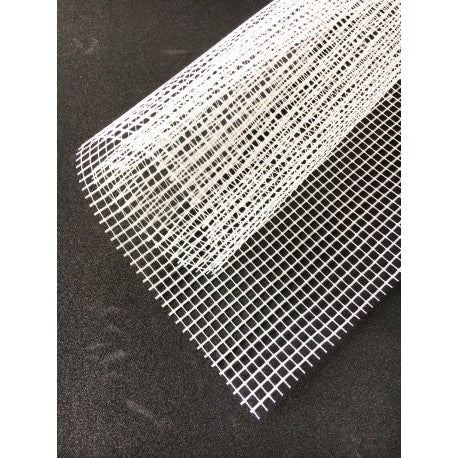

However, many ceramic slabs (Laminam, Dekton, Neolith…) are reinforced on the underside with a fiberglass mesh. This technical mesh, often invisible once the piece is installed, plays a key role during handling and machining.

But in certain decorative or transformation processes, this mesh becomes a technical obstacle. What should you do in that case? Here’s our answer.

What is the fiberglass mesh for?

The fiberglass mesh is glued to the back of the ceramic slab at the factory to:

- Strengthen the slab during cutting, transport, and machining,

- Absorb vibrations during drilling or cutting,

- Reduce the risk of cracks or breakage, especially on large formats and thinner ceramics.

As long as it remains well bonded and does not interfere, the mesh can remain in place without any issue.

When should it be removed?

Some decorative applications require partial or complete removal of the mesh:

- Visible bonding on furniture cladding: the mesh can prevent good adhesion or precise positioning,

- Underside texturing or polishing: for material effects or visible finishes on the edge or underside,

- Complex assemblies or inserts: which require a perfectly clean surface for lasting adhesion.

In these cases, the mesh must be removed without damaging the ceramic or exhausting the operator.

The Thibaut T512: the solution for effortless, automated mesh removal

The new T512 polishing and texturing center from Thibaut was specifically designed to meet this need. Thanks to its oscillating sanding head and fully programmable parameters, it allows you to:

- Automatically and cleanly remove the fiberglass mesh,

- Work effortlessly and dust-free thanks to an integrated suction system,

- Prepare the ceramic slab for bonding, finishing, or decoration according to the project’s requirements.

The result: time savings, consistent quality, and increased safety, regardless of the ceramic type or the shape of the piece.

An ideal solution for designers, decorators, and manufacturers

With the T512, you fully showcase your materials and creations while improving productivity. The machine suits both artisanal workshops and industrial production units looking to automate their finishing processes.

Do you have a project or want to test the T512 on your own pieces?

Contact us.