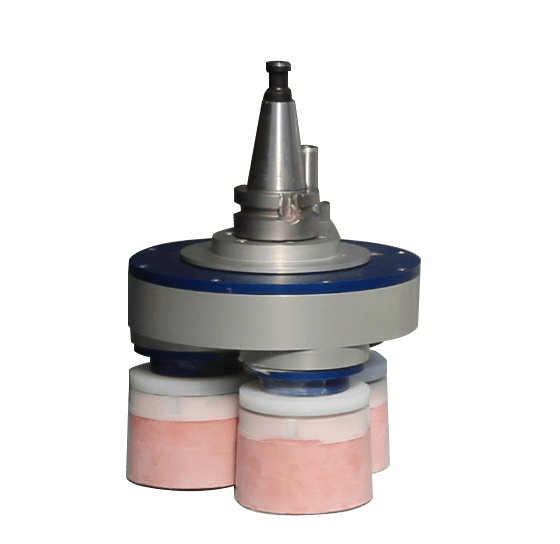

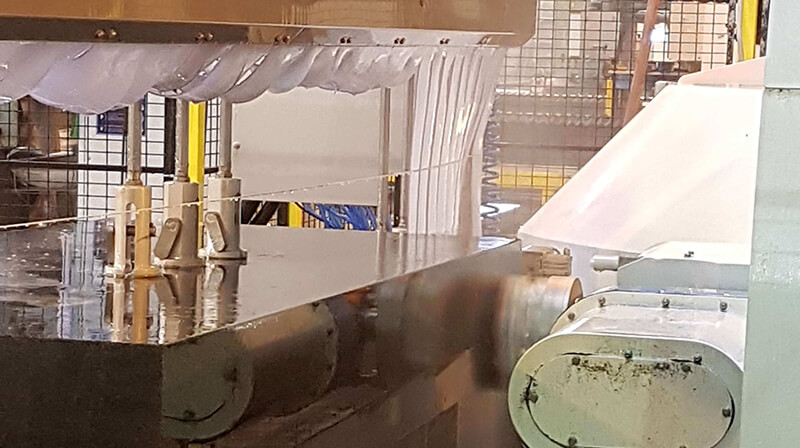

The « satellite » polishing head is used to polish and calibrate flat surfaces. It allows to obtain a very high polishing quality while having a high output. Its head has a diameter of 215 mm and is equipped with a BT 40 cone. The three abrasives have a maximum height of 70 mm. You can use conventional abrasives or resin abrasives. For textured surfaces, it is preferable to use the B3 head instead. The satellite head is compatible with several THIBAUT machines (only on THIBAUT): T108S, T818 M4 and M5, T812, T858V2, T658, T958.

Satellite polishing head with 3 abrasives

– Light and robust.

– Adaptable on many THIBAUT machines.

– Quality of polishing guaranteed.

– Easy to implement. *

– Economical & efficient: polishing with 5 grains maximum

– (diamond, 120, 400, 800, F).

– Uses conventional abrasives or resins.

– 1 Head Ø 215 mm equipped with a BT 40 attachment, for polishing granite.

– Quick setup with FRF type screws for 3 abrasives (resin or diamond) Ø100 mm.

– Maximum abrasives height 70 mm.

– Weight of the head and attachment: 10 kg.

– Wrench for abrasive coupling included.

– Possibility of installing brushes for texturing.

« satellite » polishing head prize draw

T108S V3 & V4

For polishing flat surfaces.1 revolution restraining device, 1 protection cover

T658

For polishing flat surfaces, straight or inclined edges, straight or reducing chamfers, 1 tool holder for positioning the head in the magazine

T812

For polishing flat surfaces. Manual mounting exclusively.

T818 M4 & M5

For polishing flat surfaces. 1 tool holder for positioning the head in the magazine.

T858 V2

For polishing flat surfaces, straight or inclined edges, straight or reducing chamfers… 1 tool holder for positioning the head in the magazine.

T952

For polishing flat surfaces, straight or inclined edges, straight or reducing chamfers… 1 tool holder for positioning the head in the magazine.

T958

For polishing flat surfaces, straight or inclined edges, straight or reducing chamfers… 1 tool holder for positioning the head in the magazine.

* Whatever the machine on which the head is installed, an anti-rotation system is required.